PROFILE EXTRUSION

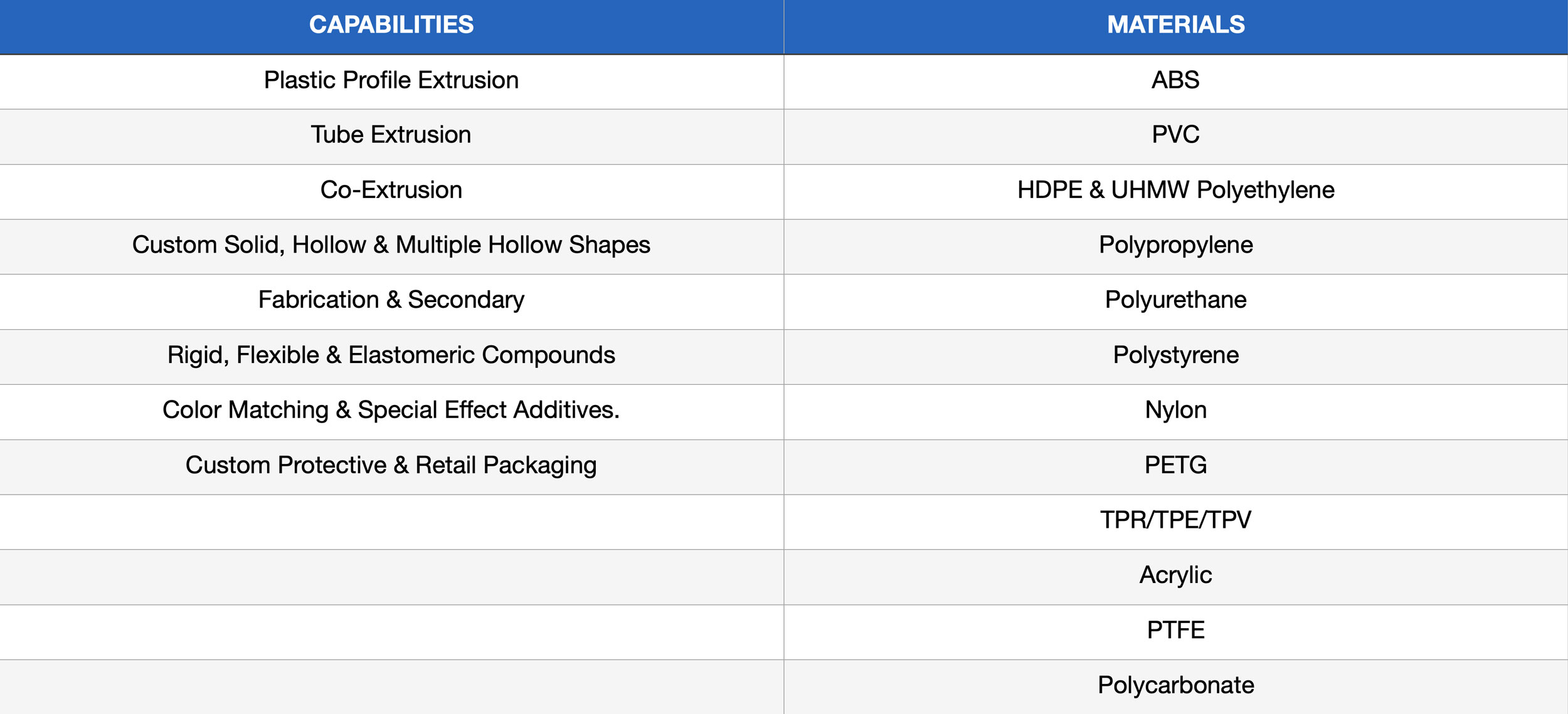

Pipes and standard or special profiles made of PVC, PU, PE and PA are manufactured on more than 10 extrusion lines. Diameters of up to 6″ and profile widths of up to 39 3/8″ can be realized. The extrusion machines used guarantee excellent surface quality and consistent dimensions. Using a special co-extrusion process, different raw materials can be processed in one operation, for example into semi-flexible foldable tubes. Through professional planning, constant renewal and expansion of the machine park as well as continuous training and further education of the BARKU employees, the production processes are constantly optimized and quality and adherence to schedules are ensured.

After the production of the individual plastic parts, they are assembled and assembled on site to form a product. All further processing steps that are necessary are carried out directly at BARKU – individually according to customer requirements. This includes welding, cutting, punching and drilling as well as, for example, printing on the products